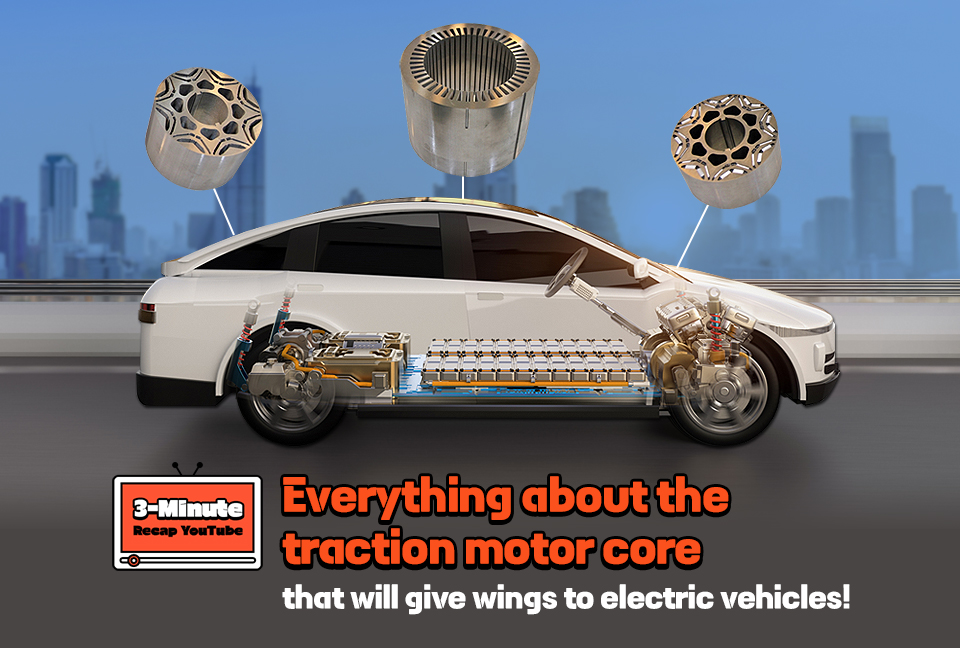

Save your valuable time. Watch a short version of a long YouTube video in just 3 minutes! In this episode, we will learn about the traction motor core, which is considered the heart of electric vehicles along with rechargeable batteries and take a look at the global market competitiveness of POSCO INTERNATIONAL and POSCO MOBILITY SOLUTION, both of which have emerged as leaders, along with major automobile companies worldwide, as materials suppliers for the future mobility industry. Let’s meet them!

As the automobile market paradigm is rapidly changing with a focus on electric and hydrogen vehicles, rechargeable batteries and traction motor cores, core components of electric vehicles, are in the spotlight. Accordingly, POSCO Group is expanding its position in the global eco-friendly vehicle market by making notable achievements in cathode/anode materials, which are core materials of rechargeable batteries, and traction motor core businesses. For the traction motor core business, POSCO MOBILITY SOLUTION, POSCO INTERNATIONAL’s 100% subsidiary, is responsible for production, while POSCO INTERNATIONAL carries out marketing for domestic and overseas customers.

Rechargeable batteries are generally well-known. However, although driving motor cores have attracted great interest, many people are not sure what they are exactly or how they work. So today, three experts from POSCO MOBILITY SOLUTION gathered to answer your questions about traction motor cores. A story about traction motor cores that you can’t find anywhere else! Let’s start now.

What is the traction motor core that is in the spotlight these days?

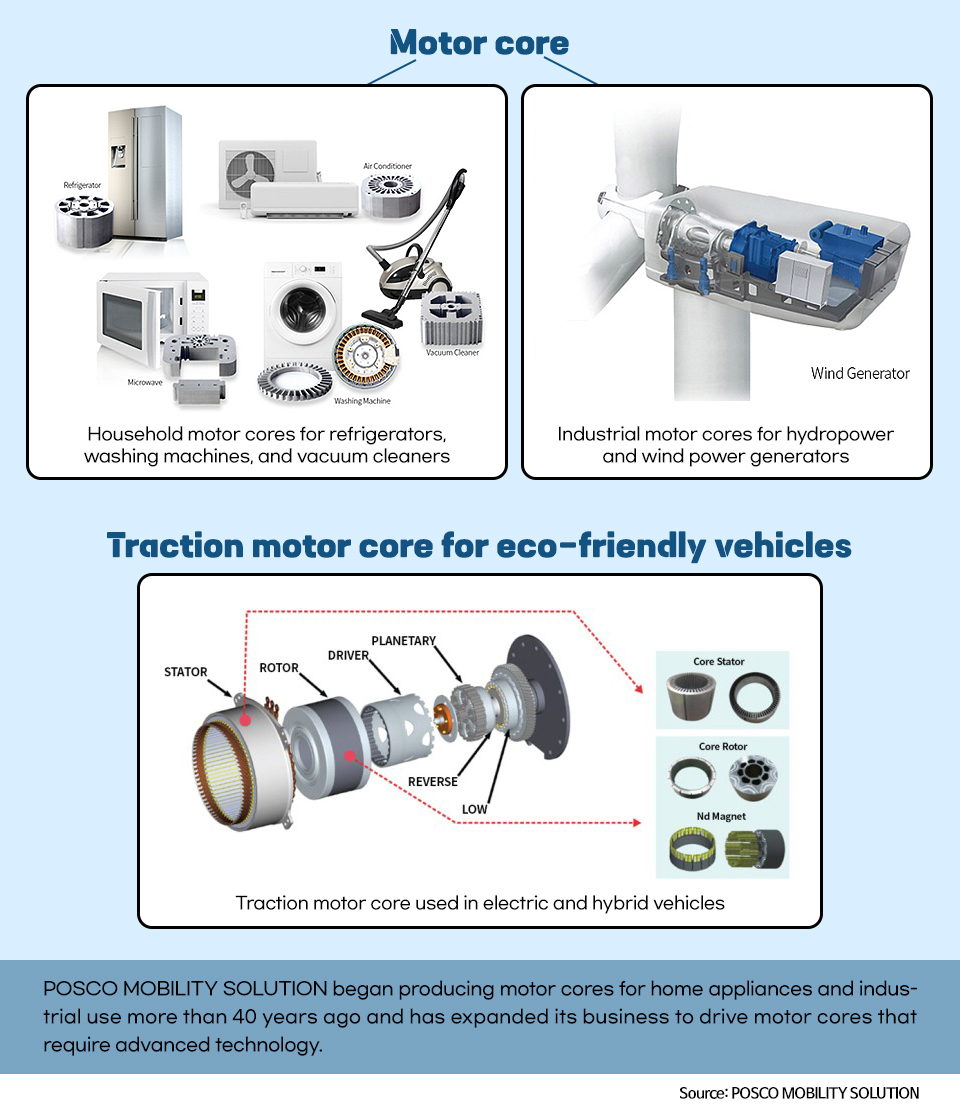

First, motor cores are parts used in devices that require rotational movement. They are used in electrical components, such as wipers, sunroofs, and steering systems, that provide convenient features for automobiles, as well as home appliances such as refrigerators, washing machines, air conditioners, and vacuum cleaners.

Traction motor cores are next-generation motor cores with additional advanced technology. They are the key part of the drive motors used in eco-friendly vehicles such as electric and hybrid vehicles. They convert electrical energy into kinetic energy to move electric vehicles. If you compare it to an internal combustion engine car, the drive motor is an engine, and the traction motor core is the core component of an engine!

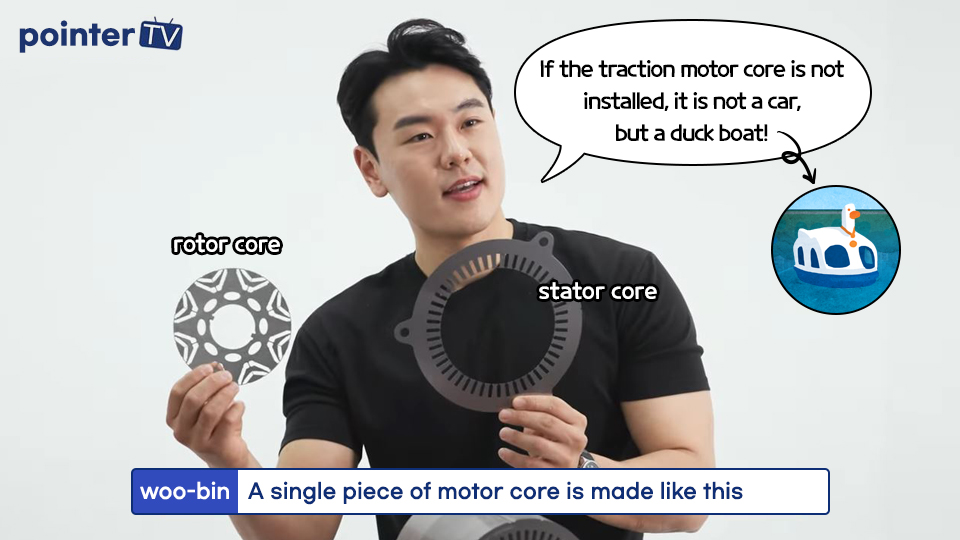

So, how does a traction motor core drive an electric vehicle? A traction motor core consists of a stator* stacked on the outside and a rotor* on which the drive motor rotates. The core is made in different heights and sizes depending on the output structure, such as hybrid and pure electric vehicles. When electricity is transmitted to the copper wire inserted into the stator, a magnetic field is formed, and the permanent magnet inserted into the rotor reacts with the magnetic field and rotates to generate power, which is transmitted to the shaft*, causing the vehicle to move.

*Stator: A fixed part in a generator or electric motor

*Rotor: A rotating part in components related to rotational motion, such as a generator or electric motor

*Shaft: A round bar-shaped mechanical part that transmits power through rotary or linear reciprocating motion

The traction motor core determines the efficiency of the car motor. As a result, it significantly affects the driving range and fuel efficiency of electric vehicles. Just as a vehicle cannot move without an engine, a traction motor core is a key component for an electric vehicle, and it is no exaggeration to say that an electric vehicle would be useless without a traction motor core. POSCO MOBILITY SOLUTION manufactures such high-quality traction motor cores.

Why should global finished automobile manufacturers choose POSCO MOBILITY SOLUTION?

Production of high-quality traction motor cores with its internally developed EM-free lamination technology

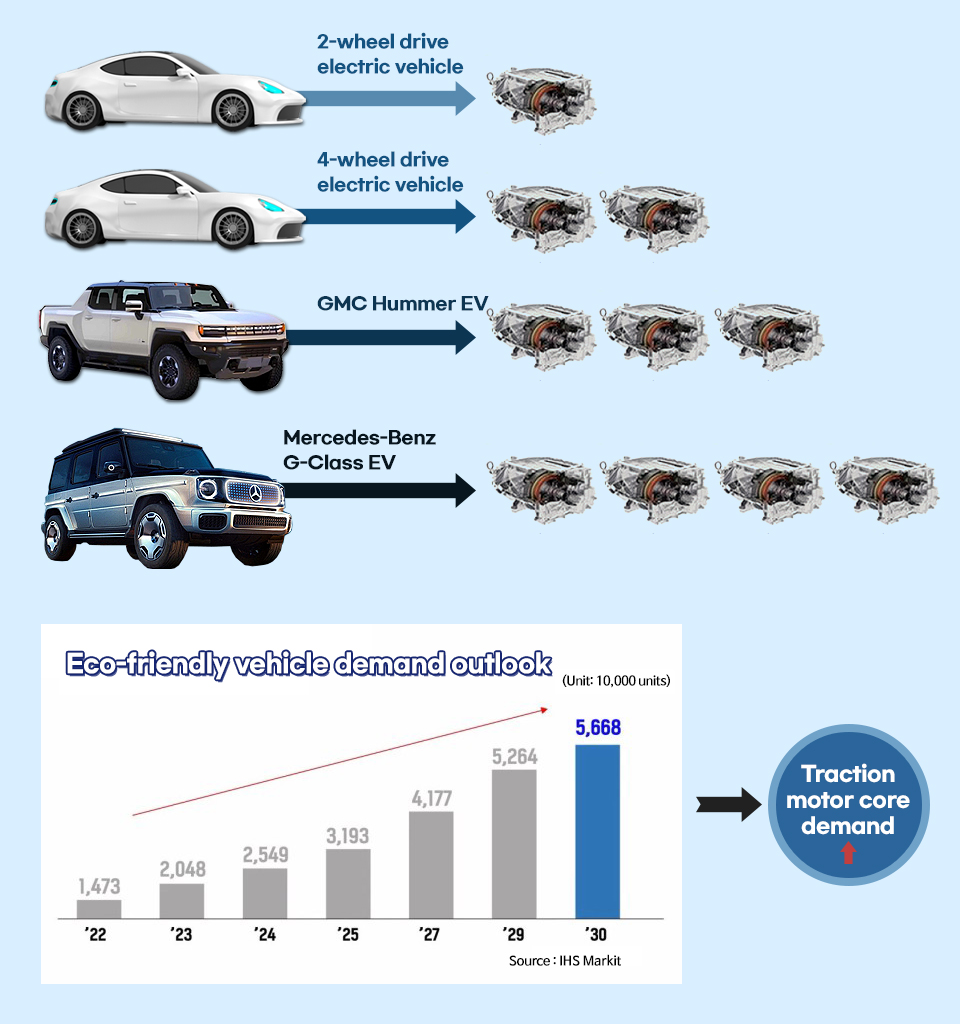

As the demand for high-performance, eco-friendly vehicles increases, so does the number of drive motors. While a vehicle used one drive motor in the past, a four-wheel drive vehicle nowadays has two or even four drive motors, increasing the number of traction motor cores, each contained in a drive motor. For example, the Hummer EV, a large pickup truck made by POSCO MOBILITY SOLUTION’s customer GM, has three drive motors because of the requirement for high horsepower due to its heavy weight, and the Electric G-Class scheduled to be released by Mercedes-Benz is expected to have four traction motor cores. Therefore, the demand for traction motor cores will increase as the eco-friendly vehicle market expands, and the growth potential of POSCO MOBILITY SOLUTION is also expected to higher.

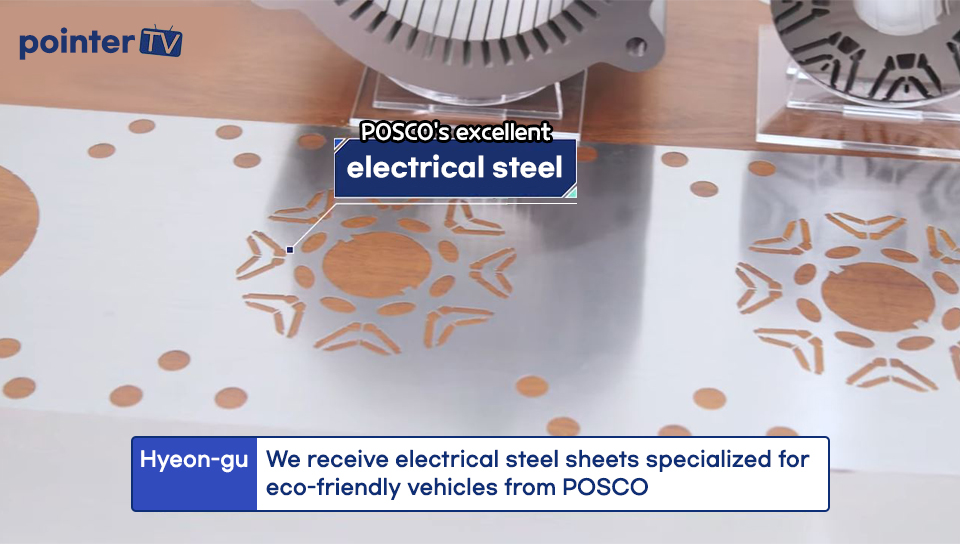

POSCO MOBILITY SOLUTION is investing heavily in improving the quality of traction motor cores to meet the market’s high expectations and demand. For example, it procures POSCO’s excellent non-oriented electrical steel sheets(Hyper NO)* and uses them as the main material for producing motor cores. Moreover, it uses a proprietary lamination method developed by its mold research center to produce high-quality traction motor cores with maximum motor efficiency and performance.

*Non-oriented electrical steel sheet: Electrical steel sheet that has consistent magnetic characteristics in all directions and is mainly used for rotational parts such as generators and motors

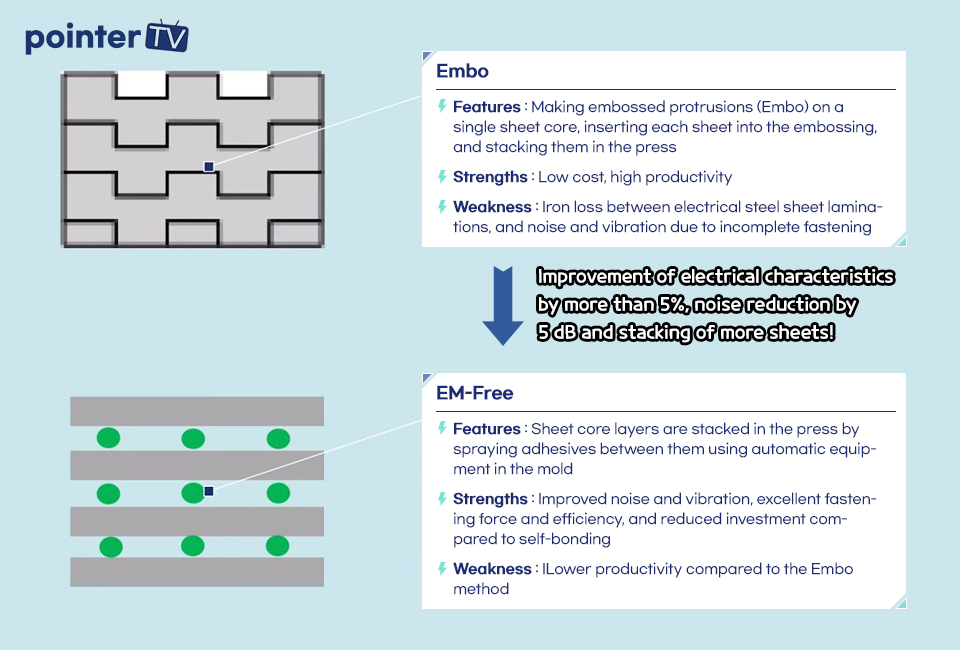

EM-Free (Embo-Free) lamination technology is used, which involves inserting POSCO’s electrical steel plates into a press where a mold is installed and automatically applying a bond to a single sheet of core that is made by punching according to the design and stacking them in hundreds of layers. The stacked cores go through hardening and cooling processes to ensure high quality. They are extracted in a back pressure system and fastened to the shaft by inserting a permanent magnet into the rotor.

The final traction motor core is completed when they are assembled with the stators. The traction motor cores produced with these complex processes are laminated more than 10 times more tightly than the embossing (Embo) method, a conventional method of making embossed protrusions and inserting them into each other. As a result, they have the advantage of excellent quality with resistance to vibration and noise and excellent electrical characteristics.

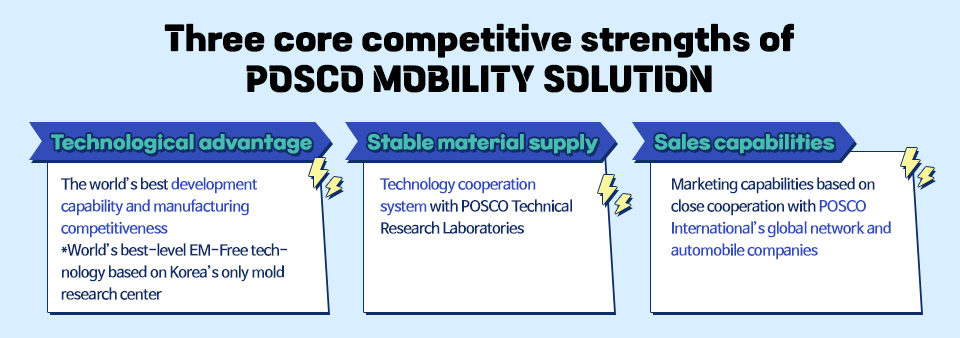

POSCO MOBILITY SOLUTIONpossesses three core competitive strengths that enable it to steadily expand its position in the traction motor core market. The first is that, as mentioned earlier, it has world-class EM-Free technology based on its mold research center, which is considered the key to the motor core business and is the only one of its kind in Korea. It also has unrivaled development capabilities and manufacturing competitiveness. It plans to secure the best-quality manufacturing competitiveness with robot automation systems by continuously developing new technologies.

Second, it can stably supply materials through synergy with group affiliates. As the production of electric vehicles has increased, the demand for motor cores has also increased, resulting in a tight supply of electrical steel sheets. However, POSCO MOBILITY SOLUTION has the advantage of smoothly supplying high-quality electrical steel sheets through POSCO. Moreover, it cooperates with POSCO Research Laboratories in material development, mass production, and stabilization.

Lastly, it has sales capabilities that use its infrastructure. POSCO MOBILITY SOLUTION has extensive sales channels based on the global network of its parent company, POSCO INTERNATIONAL, and it also has marketing capabilities to enter international markets. POSCO MOBILITY SOLUTION plans to continue its large-scale global expansion in the traction motor core business, which is a key component of electric vehicles, with these core competitive strengths.

Production system for more than 7 million units by 2030

POSCO MOBILITY SOLUTION is steadily building the traction motor core production network at home and abroad to strengthen competitiveness and continuously expand the business. The company plans to complete a 2 million unit production system, with 1 million units each in Cheonan and Pohang in Korea. The Cheonan plant is currently in full operation to produce 1 million units per year, and the Pohang plant built a new plant exclusively for producing 1 million traction motor cores in 2022 and is gradually increasing its production capability.

Overseas, it is also accelerating production by completing new plants in China and Mexico. The Chinese plant, which began mass production in the fourth quarter of last year, is expected to produce 1 million units annually. Moreover, its Mexican plant, which began construction in July 2022 and was completed in October 2023, plans to produce 1.5 million units to actively target the North American eco-friendly vehicle part market. It also plans to build a plant to produce 1 million units per year to meet the rapidly increasing demand for electric vehicles in North America, a plant to produce 1.2 million units per year in Poland for Europe, and a plant to produce 300,000 units in India to complete its global production base.

Orders are expected to increase actively as it builds additional plants worldwide. POSCO INTERNATIONAL plans to have a global production system with plants in Korea (Pohang and Cheonan), Mexico, Poland, China, and India by 2030 and expects to increase sales of traction motor cores to more than 7 million units per year. The company plans to secure a global market share of more than 10%.

It recently won orders for 1.03 million traction motor cores for electric vehicles that Hyundai and Kia Motors will manufacture locally in Europe for the first time from 2025 to 2034. It confirms the company’s plan to expand its eco-friendly mobile business domain to Europe. It will supply 550,000 and 480,000 traction motor cores to Hyundai and Kia Motors’ Turkey and Slovakia plants, respectively, through Hyundai Mobis Slovakia’s electric module plant.

POSCO INTERNATIONAL and MOBILITY SOLUTION aim to become the strongest players in the eco-friendly part market with unrivaled competitiveness in the traction motor core business area, which is the heart of electric vehicles! Please continue to support their rapid progress, which will continue to play a key role in the electric vehicle value chain!