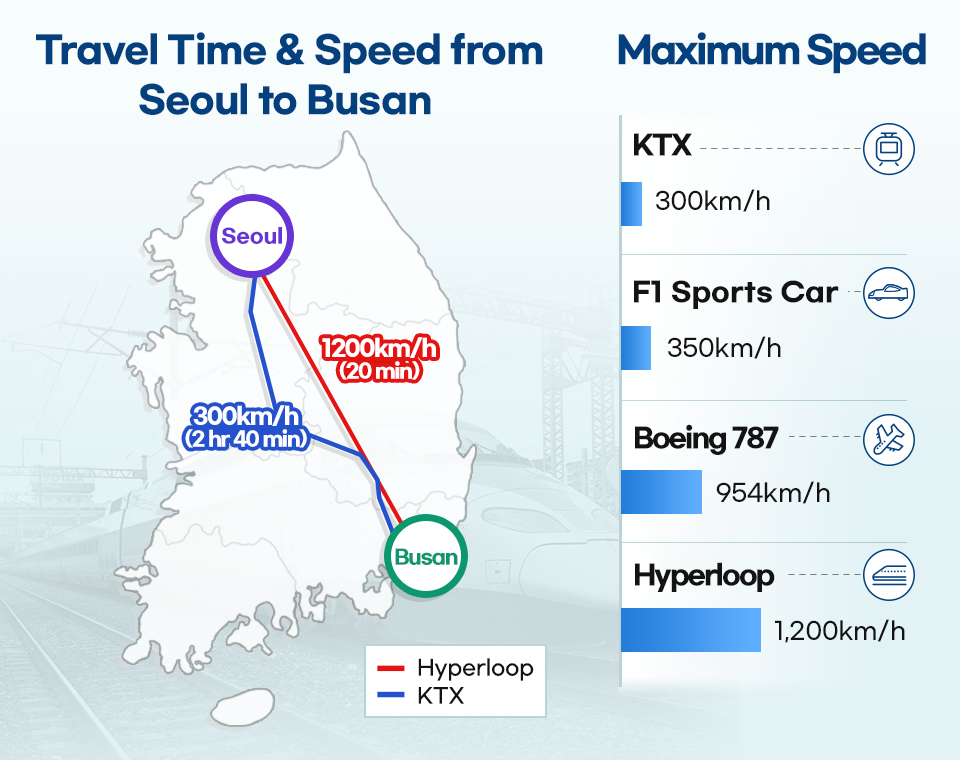

Cyber Formula is an animation those interested in car racing would have definitely seen when younger (Korean version title: Racer of Glory). The most exciting moment in the cartoon would be when the main character uses the “booster” function during a race. When the booster is activated, the car changes to a high-speed driving mode where it runs at a speed close to “sonic” and overtakes all other cars. Actually, a car dashing away at the speed of sound is an imaginary idea. In reality, the maximum speed of a F1 race car is about 350 km/h while the speed of sound reaches 1,224 km/h — about four times faster. However, it seems that this cartoon-like “sonic speed” transportation could be materialized in about 10 years. That is, if “Hyperloop” is commercialized.

The maximum speed of hyperloop is about 1,200km/h, comparable to the speed of sound and faster than the Boeing 787. The travel time from Seoul to Busan may take merely 20 minutes. It means that commuting from Busan to Seoul can become possible. When the Korean Train Express (KTX) was first introduced in 2004, it became possible to travel Seoul-Busan back and forth within a day. With the hyperloop, this would be shortened to within an hour.

The concept of hyperloop became widely known to the public when Elon Musk, CEO of Tesla and SpaceX, mentioned it. When he first unveiled the concept of Hyperloop in 2013, demonstrating a high-speed train in the form of a capsule moving inside a vacuum tube, some critics were skeptical, dismissing Musk’s idea as being science fiction. However, research on this idea began as it received spotlight from the media, and last month, a U.S. company, Virgin Hyperloop One (VHO), succeeded in the first manned test run in an experimental tunnel in the Nevada desert near Las Vegas. Since it was still in the test phase, the tunnel was just 500m long and the speed was only 172km/h, which is 1/7 of the speed of sound. However, it was enough to prove that the concept of traveling within a vacuum tube wasn’t science fiction anymore.

※ Image Source: Virgin Hyperloop (VHO) official website

Then what is the principle that enables the hyperloop to travel within the vacuum tube? To understand this, let’s first look at how a hyperloop can reach the speed of sound.

l Trains Are Fast. Airplanes Are Faster.

Why are planes faster than trains? Of course, the fact that airplanes are equipped with jet engines would be one answer. However, there is another factor that can’t be overlooked: the traffic environment. Trains travel on the ground while planes fly high up in the sky, which results in significant differences at speeds.

Usually, planes fly at an altitude of 10 km, and the air pressure here is only 30-40% compared to that of the surface. As the air pressure and the air density decreases, the air resistance to the plane body decreases as well, so it becomes possible to move faster and more efficiently with less energy. If the Boeing 787 can achieve a speed of more than 900 km/h at 30-40% air pressure compared to the ground, theoretically, a hyperloop can reach close to the speed of sound since the air pressure on the hyperloop body is 1/1,000 — a vacuum state of 0.1%.

In the field of aviation and rockets, the unit “Mach” is more frequently used rather than “km/h”. This is because, in the air, the actual travel speed is greatly affected by traveling conditions, such as air pressure and temperature, so a reference point is required to allow comparison. The reference point here is the speed of sound, which is 1,224 km/h, and it is named “Mach 1”.

l Hyperloop: A Magnetic Levitation (Maglev) Train Traveling Within a Vacuum Tube

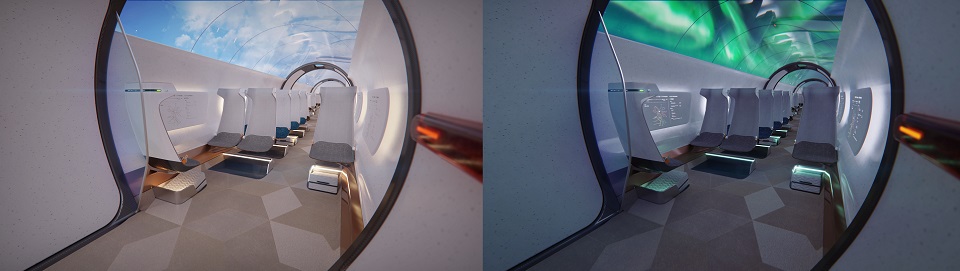

Now let’s look at the structural principle of the hyperloop body and the vacuum tube. Picturing a “maglev train” would help to understand the structure of a hyperloop. The driving principle of hyperloop is maglev, where the magnets placed on the train and the track interact. As the end of the magnets meet, they interact in two different ways: 1) the train pushes itself away from the track or 2) the train pulls itself to the track. Both systems enable the train to travel swiftly through the vacuum tube like a missile. The maglev trains in Shanghai and Incheon Airport adopt the first system, while the Japanese SCMaglev adopts the second. The biggest advantage of maglev is the absence of friction with the track which minimizes routine maintenance, and this is the same in the case of the hyperloop as well. Besides the fact of being super-fast, another difference the passengers might observe between the hyperloop and conventional train is that hyperloop trains do not have any windows since they are made in capsule forms to minimize air resistance and weight. The names of the hyperloop’s parts might be somewhat unfamiliar, but they are actually quite straightforward. The rails are called “track”, tunnels are called “tubes,” and trains are called “pods”.

▲ An image of the sky and the aurora projected on the ceiling of a hyperloop pod (train) (※ Image Source: Hardt Hyperloop)

VHO, which possesses a maglev train, created a hyperloop train in life-size, and in 2017, the train recorded a maximum speed of 386 km/h in an unmanned trial. In June 2019, a hyperloop company Hardt Hyperloop demonstrated the world’s first maglev switch in a 30m full-scale test facility in the Netherlands. Formerly, the maglev switching was done by moving the track but Hardt Hyperloop succeeded in developing a system where the train can go on and off the track, like a highway, thus improving the operational efficiency of the hyperloop.

In Korea, since the Korea Railroad Research Institute succeeded in accelerating a model vehicle under 1kg to 700km/h for the first time in the world eight years ago, development for a Korean-type hypertube (HTX) and an ultra-high-speed capsule train has begun. On November 11, the model vehicle recorded a top speed of 1,019km/h in a test scaled down to 1/17, showing world-class technology.

l Hyperloop Commercialization: The Stability of the ‘Tube’ and Material Technology Are Key

The advantage of Hyperloop isn’t just its speed. Since it moves in a vacuum tube, it doesn’t create any noise. It has no restrictions regarding the weather, such as fog or typhoons, and there isn’t any CO₂ generated as well. The energy consumed for transporting one person per 1km is 8% compared to airplanes and 35% compared to high-speed trains, while the cost being economical as well.

However, in order for Hyperloop to be commercialized, there are still some issues to be resolved. Imagine a train running at a speed of 1,200km/h within a tube of tens or hundreds of kilometers in a vacuum state.

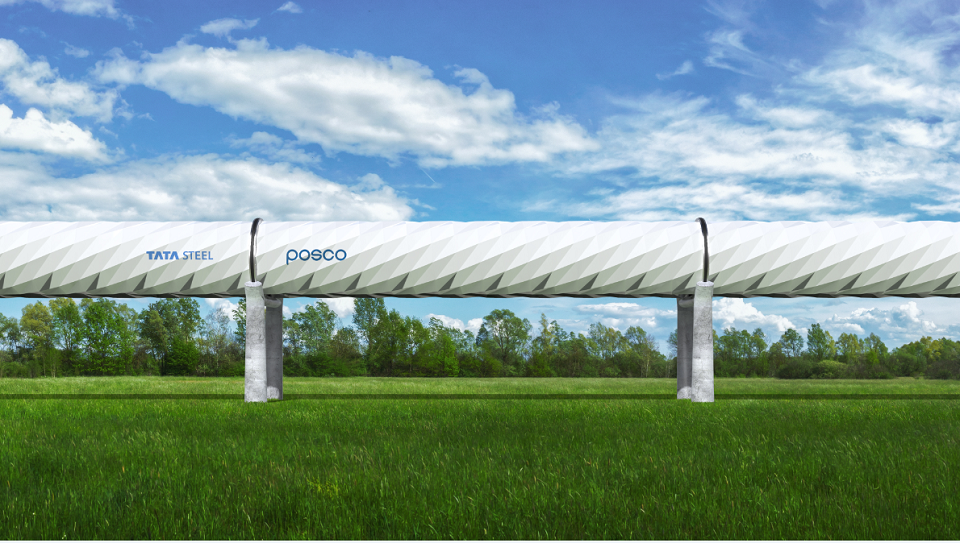

※ Image Source: Hardt Hyperloop

The first issue is securing airtightness and safety. Since the long tube has to be kept in a vacuum state, ensuring airtightness is a must, as well as the safety of the train which is running at super high speed. A test run of a manned train traveling 500m at 167km/h was successful, but there is still a long way to go to travel tens or hundreds of kilometers at 1,200km/h. The tubes that make up the track of the hyperloop must not only be able to withstand the load of the tube itself but also the load of the pod, the shock, and thermal expansion caused by high-speed driving. Another factor the tube must withstand is air pressure, which is difficult for objects within a vacuum state. If the tube deforms or cracks due to these factors, it could lead to big accidents. This is why the material and structural technology used to fabricate the tube is crucial.

The second issue is overcoming the “Kantrowitz limit”. The inside of the tube is supposed to be in a vacuum state, but little amounts of air remain inside the tube. When the space between the train and the tube narrows and the speed of the train approaches the speed of sound, the air flow in the tube is blocked at some point. This is called ‘air suffocation’, or ‘Kantrovitz limit’ in technical terms. How could this be overcome? Sufficient space must be secured between the train and the tube so that the air flow within the tube is not blocked, and this entails increasing the size of the tube to find the optimum diameter.

The third issue is ensuring economic feasibility. Concrete, carbon fiber, and steel have been reviewed as tube materials. Concrete is economical but lacks airtightness, while carbon fiber is costly and lacks machinability. Accordingly, steel, which is of reasonable cost and features excellent airtightness and workability traits, has been evaluated as the most appropriate material for the tube.

l POSCO & Tata Steel Europe Get Together for Hyperloop

▲ A schematic diagram of a hyperloop tube jointly developed by POSCO and Tata Steel Europe

How much steel would be consumed to make a hyperloop tube out of steel? Experts say that it will take about 2,500 tons of steel per kilometer to manufacture a tube with a diameter of 4m, so the steel for hyperloop tubes is likely to become a new large-scale market in the future for the steel industry. As the key to shortening the period of Hyperloop commercialization depends on the tube manufacturing technology. So, it is important to preoccupy the market and set the standards by developing specialized steel materials optimal for producing tubes.

That is why POSCO held an agreement ceremony with Tata Steel Europe (TSE) on November 6 and decided to jointly step forward to develop steel materials for hyperloop. The cooperation will cover the overall hyperloop business field, including developing steel materials, structural solutions, and participating in global projects. Since POSCO possesses several optimized steel materials and technical solutions for hyperloop and Tata Steel Europe has expertise in tube structures, the cooperation of both companies is expected to create great synergy and is evaluated as an exemplary open collaboration case between global steelmakers.

▲ POSCO and Tata Steel Europe signed a business agreement regarding hyperloop via conference call.

Realted Article

• POSCO and Tata Steel Join Forces to Develop Hyperloop Tubes

Many hyperloop companies, such as VHO, HTT, and Hardt Hyperloop are now competing for hyperloop construction around the world. VHO, which succeeded in the world’s first manned test run in Nevada, U.S., is working on two projects linking Mumbai to Pune in India and Dubai to Abu Dhabi in the UAE. The American company HTT is carrying out the world’s first commercial project connecting the Expo2020 exhibition center and Al-Maktoum International Airport in Dubai. In 2019, Hardt Hyperloop announced its plan to build a 3km hyperloop test center in the Netherlands, where hyperloop trains will be tested up to 700 km/h. Considering this speed of advancement, the day when Seoul and Busan will be connected by hyperloop may come sooner or later. And if POSCO joins in, the day might be expedited than expected.